About Us

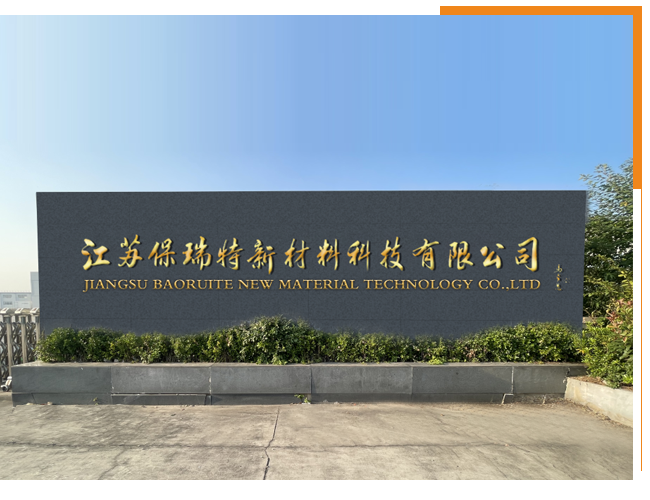

JIANGSU BRIGHT NEW MATERIAL TECHNOLOGY CO.,LTD

SINCE 2021

CORROSION PREVENTION, SCALE PREVENTION, AND WAX FORMATION PREVENTION OF MPS®COATINGS IN OIL AND GAS PRODUCTION

Jiangsu Bright New Material Technology Co.,Ltd (a Sino Malaysian joint venture) is located in the Taixing Industrial Park of Jiangsu Province, China. It focuses on the research and development,production, and sales of new materials and high-performance oil and gas pipeline coating technology, the application of petroleum equipment technology, and the incubation and incubation of high-tech industries, as well as supply chain management services and other industrialinvestments and services.

The first and second phases of the project involve approximately 600 acres of industrial land,with an investment of 5 bilion RMB, and an annual production of 2 million tons of MPS High performance oil and gas pipeline anti-corrosion coating production factory, 300000 sets of special connection buckle product production factory, new material research and development center,bigdata center, and internationalconferencecenter.

View More →

The Reason Why MPS® ?

MPS®Anti-corrosion, anti-scaling and anti-waxing of coatings in oil and gas production

New generation of coating and

spraying technology

MPS® thermoplastic materials

Epoxy phenolic is a hot strand material

MPS®The coating can be repaired locally

Low cost and good reliability

High temperature corrosion resistance: 150 ℃ wet environment, 200 ℃ dry environment

Better chemical resistance

double sparse performance superior

16% CO₂, 12% H2S wet environment

corrosion resistance

Higher corrosion resistance, more than 5

times that of epoxy phenolic

Better attachment ability

Meet QHSE requirements,

no pollution during production

Our production process

MPS®Schematic Diagram of Spraying Process Flow of Inner Coating of Oil Casing

Incoming inspection of oil pipe

01

Thread cleaning and protection

02

High temperature degreasing, etc.

03

Sand blasting derusting

04

Purge and dust removal

05

Bottom layer liquid spraying

06

bottom plasticizing

07

Surface powder spraying

08

surface layer plasticizing

09

Leak point detection

10

Coating thickness measurement

11

External oiling, spray marking and packing

12

Finished goods received or shipped

13

News

Explore more information about PORTT